Information

History

Since 2013

Beginning

The Torus Ti frame brand came out of the search for off road speed. Clee Cycles were building light weight mountain bikes for xc racing. 26” hardtails were the go-to set up as they were lighter and accelerated and climbed faster than full suss bikes. Carbon was starting to dominate as the frame choice and although they could be built with compliance – most frames were harsh to ride. The first game changer was the use of tubeless tyres. Stan’s in America invented an ultra-light tubeless rim. Clee Cycles started importing these and were one of the first wheel builders to build light weight tubeless wheels. Not just puncture protection – these wheels and tyres gave a sublime smooth, floaty ride and incredible corner grip. The bikes were built with the light weight KCNC components and to exhibit these parts we decided a titanium frame would be perfect. We called on Justin Burls (Burls Bicycles) to supply the frame and the bike was built. Tubeless 26” wheels,100mm fork and a slack (for the time) 70 degree head angle – this bike was a game changer. The way it smoothed out the trail was amazing. Singletrack Magazine tested it and said it was fast – but the head angle was too slack, And look where we are now!

It was on display at the Cycle Show in London at the time bigger wheels were being talked about - when the seed was set for Torus. Knowing how well the 26” bike rode – what would it be like with 27.5” or 29” wheels? We needed a titanium hardtail with big wheels – so decided to create our own brand. The Torus Ti29 was built for XC and XC marathon racing. Long and low, light and fast.

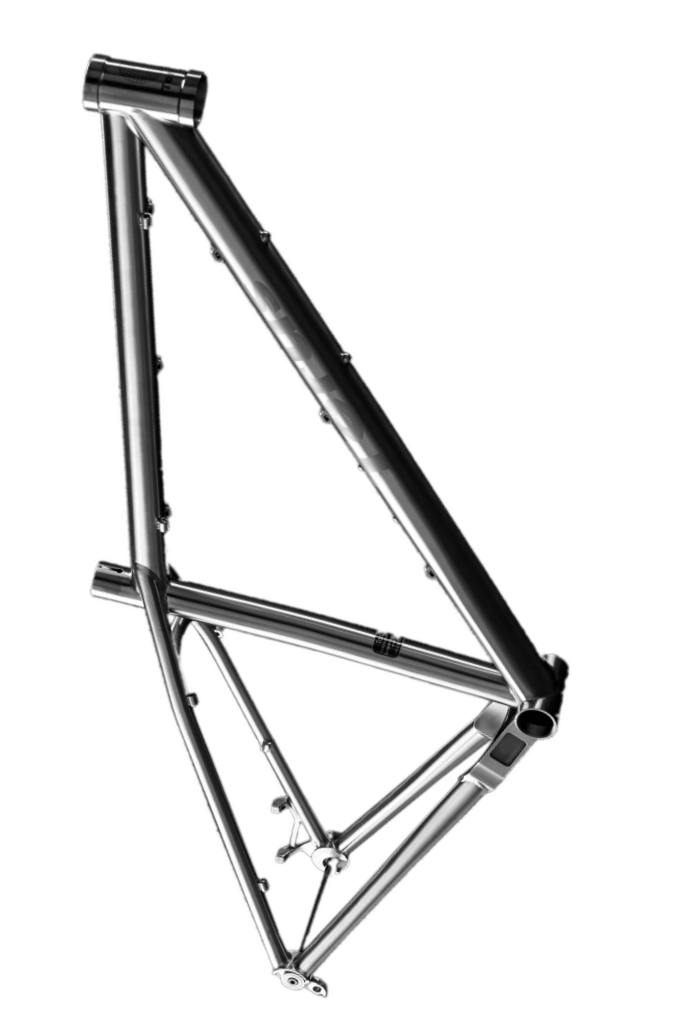

We liked the traditional metal frame look – and have kept that as a constant to this day! Machined headtubes and BB shells, round tubes and perfect weld beads. We found that plain gauge oversize tubes performed as well as the expensive butted tubes. Ti-3Al-2.5V alloy tubes were chosen due to weldability and availability, and Ti-6Al-4V for machined parts and dropouts. 73mm BSA threaded bottom bracket shells are still the best, and a 44mm internal diameter headtube to keep the traditional look. What has changed are the standards that have progressed the mtb world, and the geometry! Originally QR dropouts and straight 1 1/8” steerers, 72 degree head angles, 73 degree seat tube angles and 100mm stems Now 148mm through axles, UDH hangers, 66 degree head angles, 76 degree seat tube angle, 50mm stems - and dropper posts. We still believe in XC bikes. We will never forget the ride on the first Ti hardtail. So we still make the Ti-29 – now the Torus Ti-XC Mk4. It’s still our favourite bike and keeps the fast, lightweight vibe of the original. 68 degree head angle, 75 degree seat angle, 100-120mm fork and 60mm stem.

Why use titanium?

When it comes to cycling, the choice of frame material plays a critical role in performance, durability, and ride quality. While carbon fibre, steel and aluminium are popular frame materials, titanium stands out as the ultimate choice for many cyclists seeking a balance of aesthetics, ride quality, performance and reliability.

Timeless Aesthetic

Our titanium frames are designed in the UK and are handcrafted from aerospace grade tubing, with a high-level of craftsmanship. The visually striking brushed-metal finish provides a timeless aesthetic that will not age or be tarnished during use.

Ride Quality

Titanium is praised for its unique ride quality, which results from its ability to absorb vibrations and offer a smooth, comfortable ride, without sacrificing performance. Titanium is a metallic material with an ideal balance of strength and weight. Due to its strength, titanium frames can be manufactured from thin-walled tubing, which provides a degree of flexibility. This natural compliance allows titanium frames to absorb road buzz and trail chatter. At the same time, titanium is lightweight and maintains excellent power transfer, making it a top choice for riders seeking both comfort and performance.

Built To Last

Once you invest in a titanium frame, maintenance is minimal. Titanium is strong and does not corrode, so you won’t need to worry about paint chips, rust, or frame fatigue over time. This makes it an excellent option for riders who frequently ride in wet or humid environments, ensuring that the frame remains as strong and visually appealing as the day it was built. Titanium frames offer peace of mind and long-term reliability.

To Summarise

While other frame materials have their advantages in specific riding scenarios, titanium offers the perfect combination of ride quality, performance, reliability and aesthetic appeal. For those discerning riders looking for a lifelong riding companion, titanium is the material of choice.

Contact Information

Email - mail@torusbicycles.co.uk

Telephone - 01746 763120